Your Safety Library

From software to safety these are the top questions

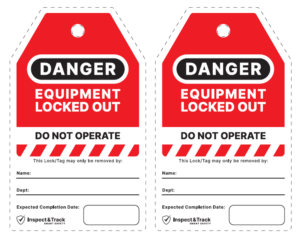

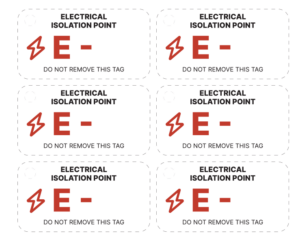

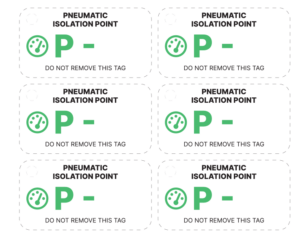

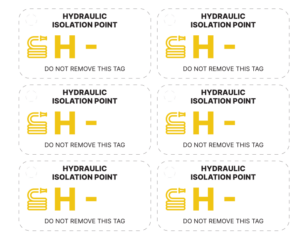

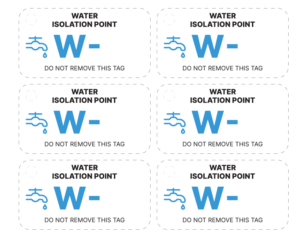

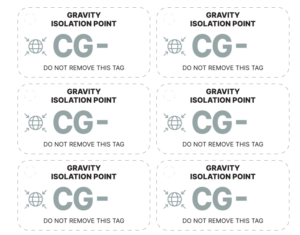

Downloads and Printables

Ready to print and use for your lockout tagout procedures.

Videos

Body placeholder for text paragraph. A paragraph is a self-contained unit of text

Featured FAQs

Frequently Asked Questions

Check out the answers to frequently asked questions about the Smart Safety Lockout Tagout software program.