This article offers an insightful look at what lockout tagout devices are, why they are important, and how best to implement them.

Lockout tagout (LOTO) is a critical safety measure that is made possible through the use of specialized equipment known as lockout tagout devices. These tools are at the heart of the process and are crucial for workers and managers alike to understand. In this guide we will dive into the specifics of lockout tagout devices, the regulations around them, various types of devices, when they should be used, and more.

What Are Lockout Tagout Devices?

Lockout tagout devices are forms of safety equipment that are used during LOTO procedures to secure and isolate energy sources on machinery. Their primary purpose is to temporarily restrict hazardous energy from being released and make machinery/equipment safe for workers to operate on.

The Difference Between Lockout and Tagout

According to the Occupational Safety and Health Administration (OSHA), a lockout device is

“Lockout Device: Any device that uses positive means, such as a lock, blank flanges and bolted slip blinds, to hold an energy-isolating device in a safe position, thereby preventing the energizing of machinery or equipment”

and a tagout device is

“Tagout Device: Any prominent warning device, such as a tag and a means of attachment, that can be securely fastened to an energy-isolating device to indicate that the machine or equipment to which it is attached may not be operated until the tagout device is removed”.

These tools tend to be used in conjunction for lockout tagout procedures and therefore are generally referred to as “lockout tagout devices”. While padlocks, hasps, and tags are some of the most commonly used devices, there are a wide range of specialized products on the market that can be used for hazardous energy control.

Lockout Tagout Devices to Be Familiar With:

Here are some of the commonly available forms of LOTO devices.

- Lockout Cables with Hasps & Locks

- Lockout Padlocks

- Circuit Breaker Lockouts

- Cable Lockouts

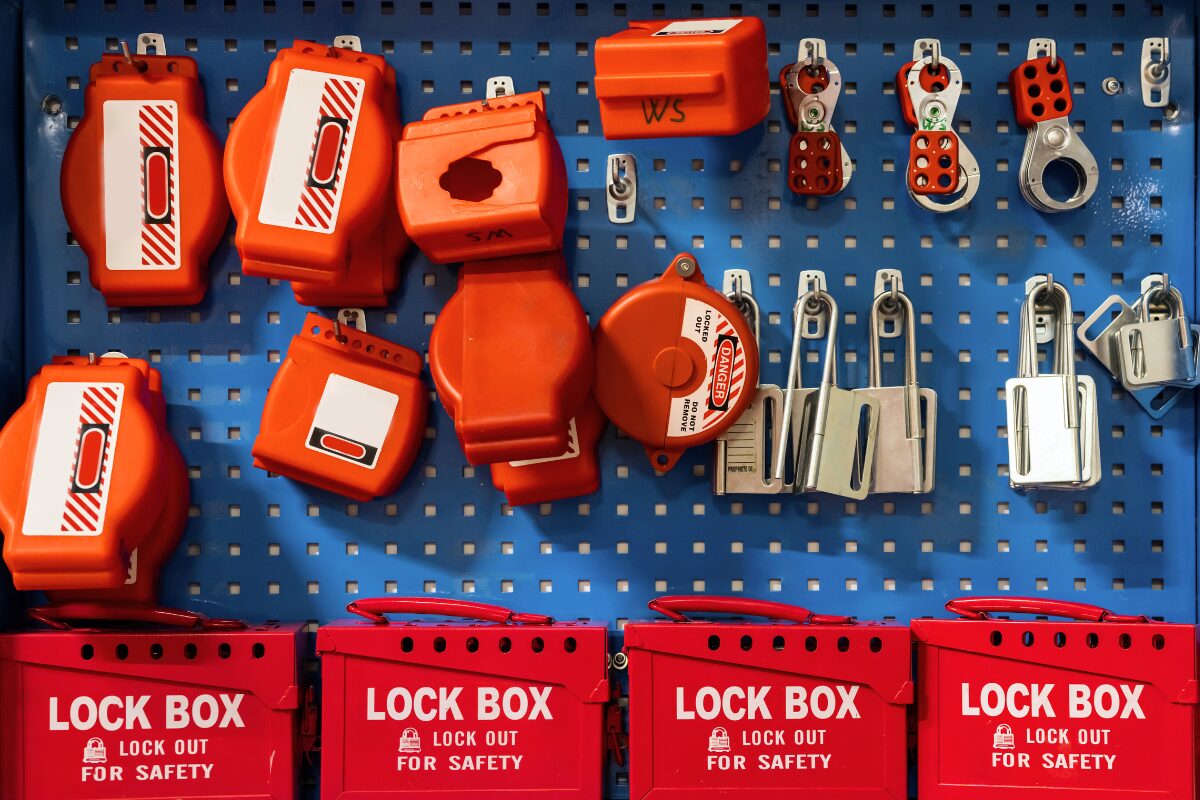

- Group Lockout Tagout Boxes

- Lockout Tagout Kits

- Lockout Tagout Stations

- Lockout Tags

- Plug/Gate/Ball Valve Devices

- Lockout/Tagout Signs & Posters

- Lockouts for Electrical Equipment

Depending on the volume and forms of machinery at a workplace, companies may own many if not all of these kinds of loto devices. Because of this, familiarity with various types of equipment will allow workers to approach a wide range of lockout tagout procedures with confidence.

The Importance of LOTO Devices

According to injury reports from the Occupational Safety and Health Administration (OSHA), an average of 85 workers are killed every year because of uncontrolled hazardous energy. Not only that, but 364 workers suffer annually from amputations. These statistics highlight just how significant proper use of lockout tagout devices are. After all, both the deaths and severe injuries mentioned were preventable.

Lockout Tagout devices serve multiple valuable purposes including:

- Protecting workers from hazardous energy

- Meeting OSHA compliance requirements

- Enabling safe servicing of machinery and equipment

- Communicating the status of equipment – whether or not it is temporarily out of service

The staggering truth is that without proper use of lockout tagout devices, even the most well-written LOTO procedures can fail to protect workers. It truly is imperative that they be understood and incorporated into safety procedures

OSHA Requirements for Lockout Tagout Devices

The 3 main requirements from OSHA regarding lockout tagout devices are that they must be durable, substantial, and identifiable. These are outlined in standard 29 CFR 1910.147 and provide a framework for the quality and characteristics of loto devices.

Durable

- According to OSHA standard 29 CFR 1910.147(c)(5)(ii), LOTO devices must be:

- Durable enough to withstand the environment in which they are used.

- Constructed of materials that can endure exposure to moisture, chemicals, and other harsh conditions.

- Tags should not deteriorate when used in corrosive environments (ex. areas where acid and alkali chemicals are handled and stored).

- Standardized in at least one way (color, shape, or size). For tags there should also be standardization of the print and format.

Substantial

- The standard further explains requirements regarding substantiality. These include that lockout tagout devices should:

- Be substantial enough to prevent inadvertent or accidental removal.

- Loto device attachment means are required to be a non-reusable type, attachable by hand, self-locking, and non-releasable with a minimum unlocking strength of no less than 50 pounds.

- Attachments for tags should be at least equivalent in design and function to a piece of all-environment-tolerant nylon cable tie.

Identifiable

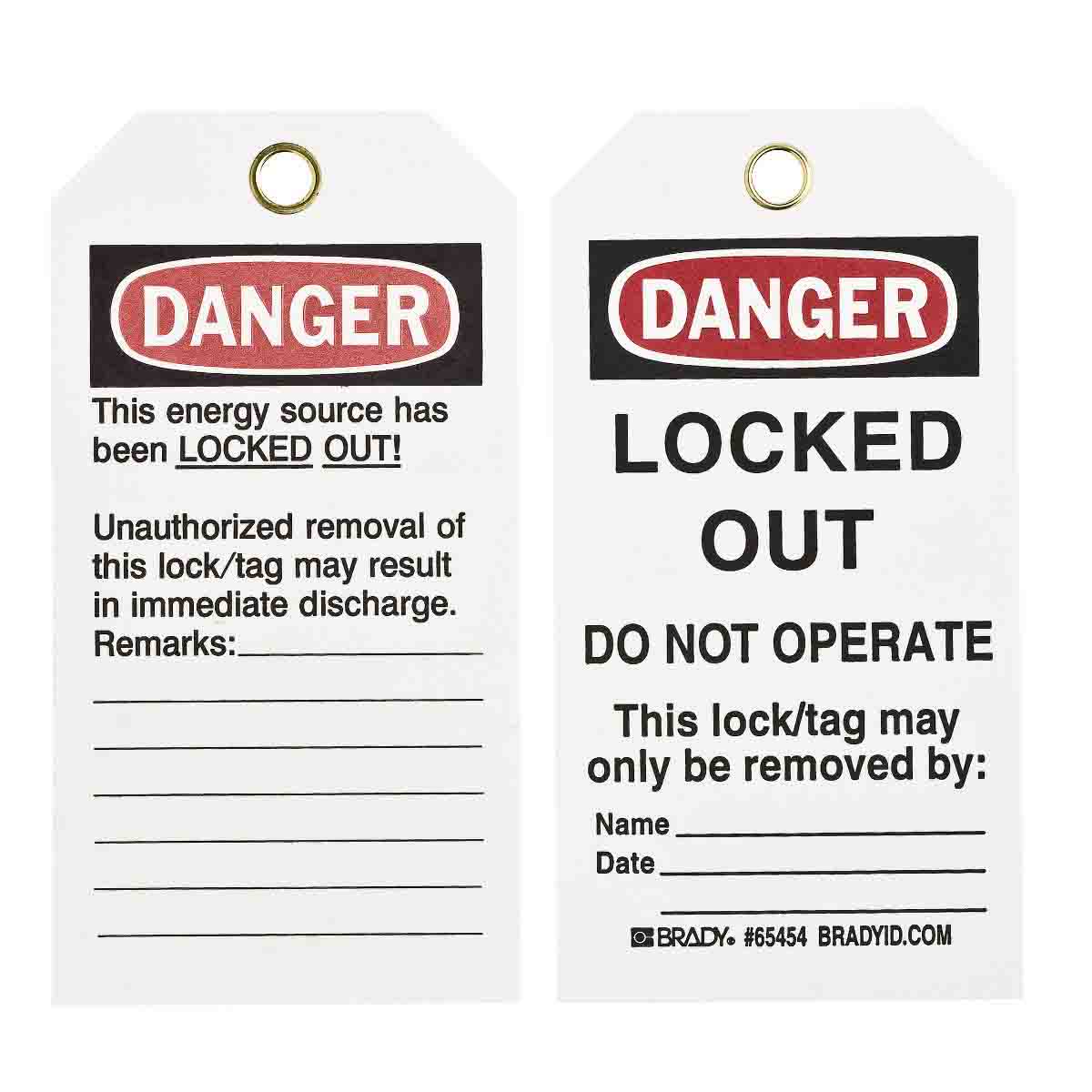

- The standard also makes a point to highlight requirements for making lockout tagout devices identifiable. In order to accomplish this, they must:

- indicate the identity of the worker who applied the device(s)

- use clear wording to warn against hazardous conditions such as Do Not Start, Do Not Open, Do Not Close, Do Not Energize, Do Not Operate.

Along with these 3 main points, OSHA also mandates that a colored LOTO tag system be standardized and used exclusively for safety. This means that there needs to be consistency in the usage and application of each color of tag as well as limited LOTO tag use (only for actions related to lockout tagout procedures). To learn more about OSHA’s recommended coloring system, see our article here.

Common Types of LOTO Devices

These are some of the most prominent lockout tagout devices to be familiar with.

| Equipment Image | Name | Description |

|---|---|---|

|

Cable Lockout Devices | Cable lockout devices can be used to loop through multiple energy points, and therefore are known for their versatility. They are generally the ideal tool for machinery that features multiple isolation points. Similar to other LOTO devices, these are secured with a padlock to restrict movement or re-energization. |

|

Valve Lockout Devices | Valve lockout devices are typically used to isolate pneumatic, hydraulic, gas, or water lines.

|

|

Electrical Lockout Devices | These are the LOTO devices designed to help isolate electrical power sources.

|

|

Lockout Hasps | Hasps are a tool which allow multiple workers to attach their personal lock to the same isolation point. They are typically used in group lockout tagout procedures and restrict the energy source from being reinstated until all the padlocks are removed. |

|

Tagout Devices | Tags are used in conjunction with lockout devices to provide workers with critical safety information such as who applied the lock and why. They are an OSHA requirement and should not be removed until the machine is being returned to service. |

*Note: All of these equipment images come from the Brady Company page.

When Should You Apply Lockout Tagout Devices to Equipment?

Lockout tagout devices should be applied any time employees are servicing or maintaining equipment where the unexpected release of hazardous energy could cause injury. This includes work involving electrical systems, mechanical parts, hydraulic and pneumatic systems, thermal energy, or stored energy sources such as springs or flywheels. If a worker must place part of their body into a machine or equipment area during service or repair, the energy source must be locked out.

LOTO devices are applied after the equipment is properly shut down and isolated, and before any work begins. They must remain in place until the maintenance is fully completed and the area is cleared for safe startup. Additionally, devices should be applied during cleaning, inspections, tool changes, or clearing jams if there is a risk of the equipment moving unexpectedly. Applying LOTO devices at the right time is critical for protecting workers and maintaining compliance with safety standards.

Conclusion

Lockout tagout devices are a key part of performing lockout tagout procedures. They serve to restrict hazardous energy from machinery and protect workers during maintenance and servicing activities. Additionally, they help with meeting OSHA compliance requirements and reducing risk in the workplace environment. Because of the essential role they play in safety, it is valuable for employers and workers alike to have a basic understanding of lockout tagout devices. It helps to become familiar with both the regulations regarding LOTO (OSHA 1910.147) and the most common types of LOTO devices. By understanding the different types of devices and how they are used, organizations can ensure their lockout tagout program is effective, reliable, and OSHA-compliant.

Whether you’re building a LOTO program from scratch or improving an existing one, investing in lockout tagout software —and training workers on its proper use—can make all the difference. Click the link to learn more.