Machine-specific lockout tagout (LOTO) procedures are no longer “nice to have”, they’re essential for compliance and safety.

If you’re still relying on generic Lockout Tagout (LOTO) instructions taped to the wall or buried in a dusty binder, it’s time for an upgrade. In today’s fast-paced industrial environments, machine specific loto procedures are no longer “nice to have”, they’re essential. Whether you’re managing a small shop or a multi-site operation, precise, equipment-based LOTO steps are the smartest way to protect your team and stay OSHA-compliant.

Let’s dive into why machine specific lockout tagout procedures are a game changer and how going digital with tools like Smart Safety Pro can take your safety program to the next level.

What Are Machine Specific Lockout Tagout Procedures?

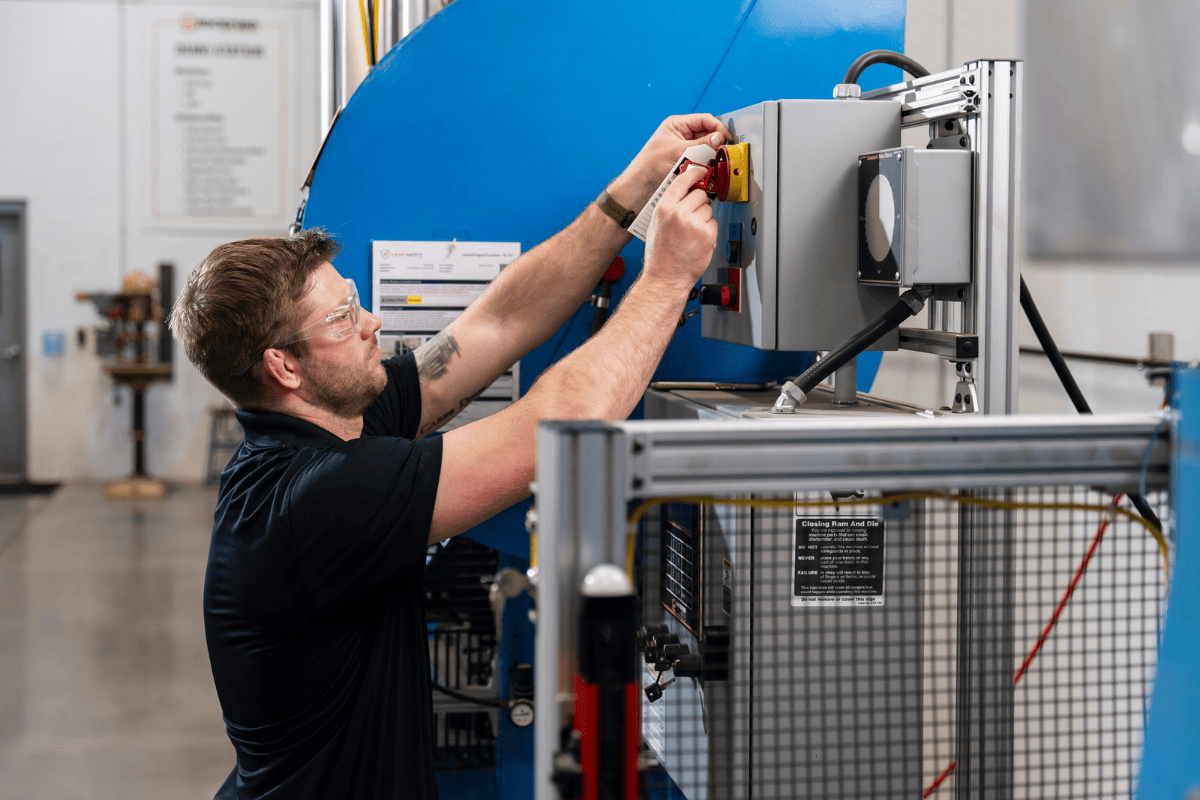

At their core, machine specific lockout tagout procedures are tailored, step-by-step instructions for isolating energy sources on a particular machine. Instead of a one-size-fits-all template, these procedures focus on the exact components, switches, valves, and energy types that a specific piece of equipment uses.

Think of it like a GPS for safe maintenance: you’re not just saying “get to the destination,” you’re giving turn-by-turn directions to prevent workers from getting lost…or worse, hurt.

Each machine specific lockout tagout procedure includes:

- The machine’s exact location and ID

- All energy sources involved (electrical, hydraulic, pneumatic, etc.)

- The type of lockout devices required

- Photo references or diagrams

- Verification steps to ensure isolation was successful

Why Generic LOTO Doesn’t Cut It Anymore

Generic LOTO procedures are risky. They’re vague, easy to ignore, and often outdated. Worst of all, they leave too much room for error. And when it comes to hazardous energy, “oops” is not a good look, especially when OSHA inspectors come knocking.

With machine specific lockout tagout procedures, you eliminate guesswork. Your team knows exactly what to shut down, how to do it, and what equipment to use. That level of precision saves time, reduces injuries, and builds a culture of safety that’s hard to ignore.

The OSHA Angle: Why It Matters

OSHA has made it clear: generic instructions won’t keep you compliant. They specifically require that procedures “clearly and specifically identify the steps” needed for each machine. If your current system doesn’t meet that bar, you’re flirting with fines and liability.

Machine-specific procedures satisfy these requirements by documenting all critical information in a repeatable, easy-to-follow format. That’s good for your people and your audit trail.

Digital LOTO: Smarter, Faster, More Reliable

Here’s where Smart Safety Pro comes in. Our digital platform is designed specifically for machine-specific lockout tagout procedures. Instead of flipping through binders or hunting down PDFs, your team can scan a QR code right on the equipment and instantly view the most up-to-date procedure.

No more version control issues. No more “I didn’t see that step.” Just accurate, standardized instructions available anytime, anywhere, even offline.

With Smart Safety Pro, you can:

- Build and manage procedures in the cloud

- Attach images and reference materials to each step

- Track activity for compliance reporting

- Update procedures instantly across all devices

Real Benefits You’ll Notice Fast:

- Fewer mistakes. When the process is clear, it’s hard to mess up.

- Less downtime. No delays from hunting down procedures.

- Improved compliance. Your audit trail builds itself.

- Happier teams. People trust systems that work—and keep them safe.

Getting Started with Machine Specific Lockout Tagout Procedures

Not sure where to start? Begin with your most frequently serviced machines. Use Smart Safety Pro’s intuitive procedure builder to document each step, test it with your maintenance crew, and deploy it across your team.

From there, scale up. Standardize procedures across your facility, then across your organization. Before long, machine specific lockout tagout procedures will be the gold standard—not the exception.

Final Thoughts

Generic safety is no safety at all. If you’re serious about protecting your team, reducing downtime, and staying ahead of compliance requirements, it’s time to go specific. Machine specific lockout tagout procedures are the future—and with Smart Safety Pro, that future is fast, paperless, and incredibly effective.

Ready to ditch the guesswork?

Start building your machine-specific procedures with Smart Safety Pro today. Your team, and your inspection report, will thank you.

For more information on these Procedures check out some of our other articles: