This article an overview of the various industries that use lockout tagout procedures to ensure safety and explains how it is incorporated.

Safety should always be a priority in the workplace; however, it is especially significant in industries that involve hazardous energy (such as electrical, mechanical, hydraulic, pneumatic, chemical, thermal, and other energy sources). Workplace environments that deal with these various types of energy rely on lockout tagout procedures to ensure that workers can safely perform their duties and maintain the operational integrity of machinery/equipment.

Lockout tagout procedures serve as a critical safety barrier which allows workers to conduct maintenance and servicing on equipment with hazardous energy sources. While LOTO is vital across many sectors, certain industries depend on it more heavily due to the complexity of their machinery, frequency of maintenance, and potential for serious injury if procedures are not followed.

Whether you’re new to lockout tagout or simply looking to better understand the workplace safety requirement, this is an article for you. Follow along as we explore some of the most common industries that incorporate lockout tagout, how they apply LOTO, and the unique challenges the face in controlling hazardous energy.

Lockout Tagout Industries

Lockout tagout ensures that machines are properly shut down and isolated before work is performed on them. This helps prevent any unexpected startup or release of hazardous energy. On the surface, lockout tagout can seem like a niche safety measure. However, it is necessary in just about any industry that utilizes large equipment or uses powerful energy to create the product or perform a service.

Industries where LOTO is commonly used:

- Manufacturing

- Food Manufacturing/Processing

- Public Utilities/Energy

- Oil and Gas

- Construction

- Warehouses

- Chemical Processing

- Other Industries

A Brief Overview of Each

Now, let’s do a deeper dive into the industries mentioned above to analyze the distinct role that lockout tagout plays in each sector and how it is implemented to safeguard workers, equipment, and property.

Why Lockout Tagout is Essential in These Industries

According to OSHA, lockout tagout is estimated to help prevent 120 fatalities and 50,000 injuries every year. While this stat isn’t industry specific, it highlights how LOTO serves as a critical form of accident prevention in the workplace across the board. Lockout tagout may seem like a non-consequential item on your checklist, but the numbers show that it is a lot more than that.

While LOTO is primarily meant to prevent worker injuries, it can also help avoid other profound problems including:

- Equipment Damage – Accidental equipment startups can result in broken machinery or operational failures.

- Compliance Violations – Failure to correctly follow lockout tagout procedures can lead to heavy OSHA fines and penalties.

- Workplace Productivity Loss – Injuries and equipment damage result in downtime, costly repairs, and legal issues.

As per OSHA reports, failure to control hazardous energy is consistently one of the top causes of workplace injuries and deaths, making LOTO an essential safety practice. Though lockout tagout contributes a little something different for each industry it’s used in, it is always a beneficial contribution.

Streamline Lockout Tagout With Software

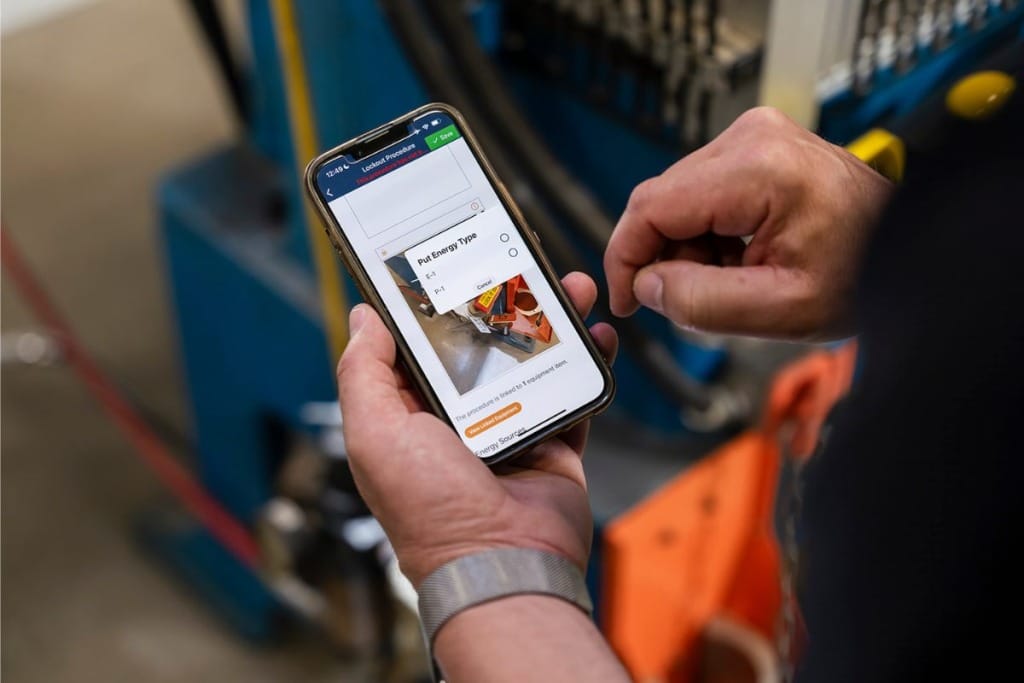

No matter what industry you are in, lockout tagout software can help make the process much easier.

Our LOTO software has been developed over the last 30 years and is specifically designed to help you write procedures, manage a LOTO program, and perform lockout tagout in a way that is easy, efficient, and effective.

Want to learn more about what our LOTO software can do and how it can make your job easier? Schedule a demo to talk with one of our specialists.

Conclusion

Lockout tagout is a crucial safety measure that protects workers across a wide range of industries from hazardous energy. It ensures that workers can safely de-energized machinery and work on it during maintenance and servicing, which helps to meet compliance requirements, prolong the lifespan of equipment, and reduce the risk of any accidents occurring.

Whether in manufacturing, construction, or chemical processing, organizations that prioritize strong lockout tagout programs not only meet safety standards but also build a culture of accountability, responsibility, and care. As industries continue to adopt automation and advanced technologies, lockout tagout remains a timeless safeguard in the evolving workplace.

For more information about how you can revolutionize your approach to safety with lockout tagout software, click the link here.