Trade in your loose papers for digital, reliable lockout tagout procedures. This article details how to use software to digitize your procedures and leverage the benefits of modern technology.

Traditionally, lockout tagout procedures have been recorded on loose paper, which can be difficult to manage, update, or access when needed. Not only that, but this approach to procedures can also result in outdated information, misplaced documents, and unclear instructions, all of which make it harder for workers to do their job well and maintain a safe, compliant atmosphere.

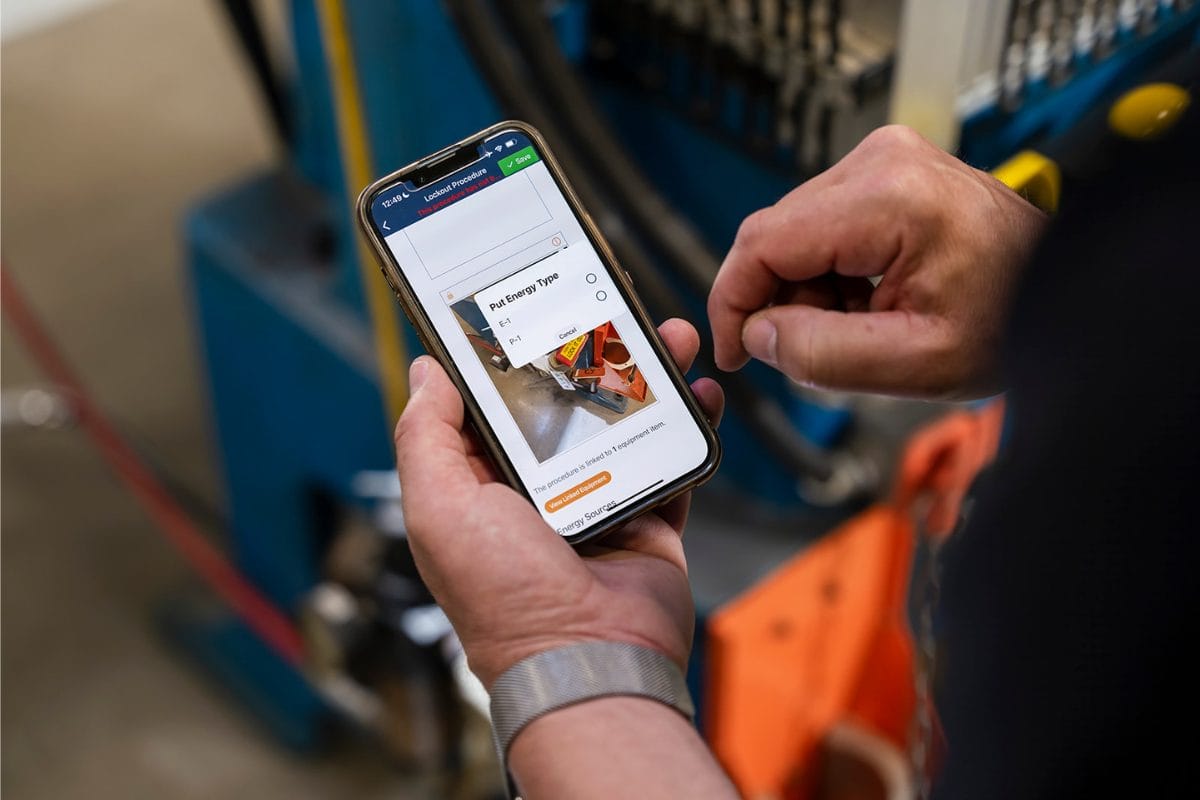

Thankfully, modern solutions have offered us a better way. Software platforms, such as InspectNTrack Smart Safety, can now be used to digitize lockout tagout procedures, organize safety efforts, and run a LOTO program. In this article, we’ll explore how to digitize your lockout tagout procedures and the benefits for your workplace.

The Challenges of Paper-Based Lockout Tagout Procedures

Printed lockout tagout procedures have been the go-to way to perform lockout tagout for a long time. In fact, many companies and workplaces still rely on paper copies to run their safety program. However, this method comes with some drawbacks that are important to recognize:

- Difficult to Access – Physical copies can be difficult to locate. Not to mention the fact that they can easily be damaged, misplaced, or become outdated.

- Time-Consuming to Update – The process of revising procedures and then distributing new versions can take a good amount of time. Additionally, it requires manual effort and necessitates reprinting, which can be inconvenient and tedious.

- Maintaining Compliance – Lockout tagout procedures that go missing or haven’t been updated in a while can lead to OSHA violations and increased safety risks.

- Lack of Standardization – When procedures are written on paper, it is harder to ensure a consistent formatting, clarity in writing, and overall uniformity. These potential variations can lead to inconsistencies across locations.

Every approach to safety is going to come with challenges, however, many of these challenges can be avoided with software. The shortcomings of paper-based LOTO make it clear that a digital approach is more accessible, efficient and reliable.

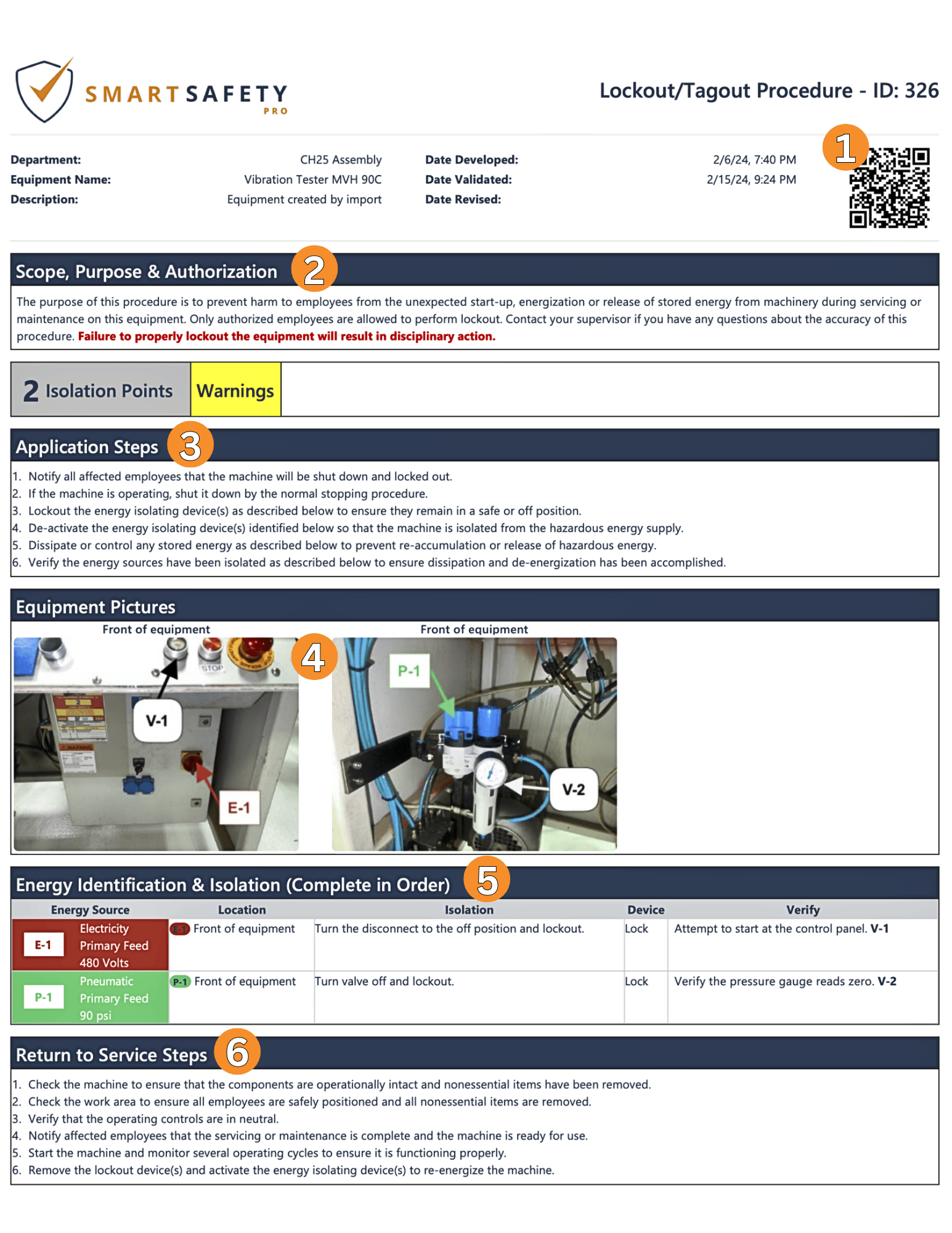

What Your Lockout Tagout Procedures Should Include

Chances are, you’ve already developed and written your lockout tagout procedures. You’re just looking to make them more accessible and adaptable for your program. However, digitizing your procedures is a great opportunity to look over the contents, improve them, and make sure that your procedures include all the necessary information. So, what information needs to be included in procedures?

How to Digitize Your LOTO Procedures in Minutes

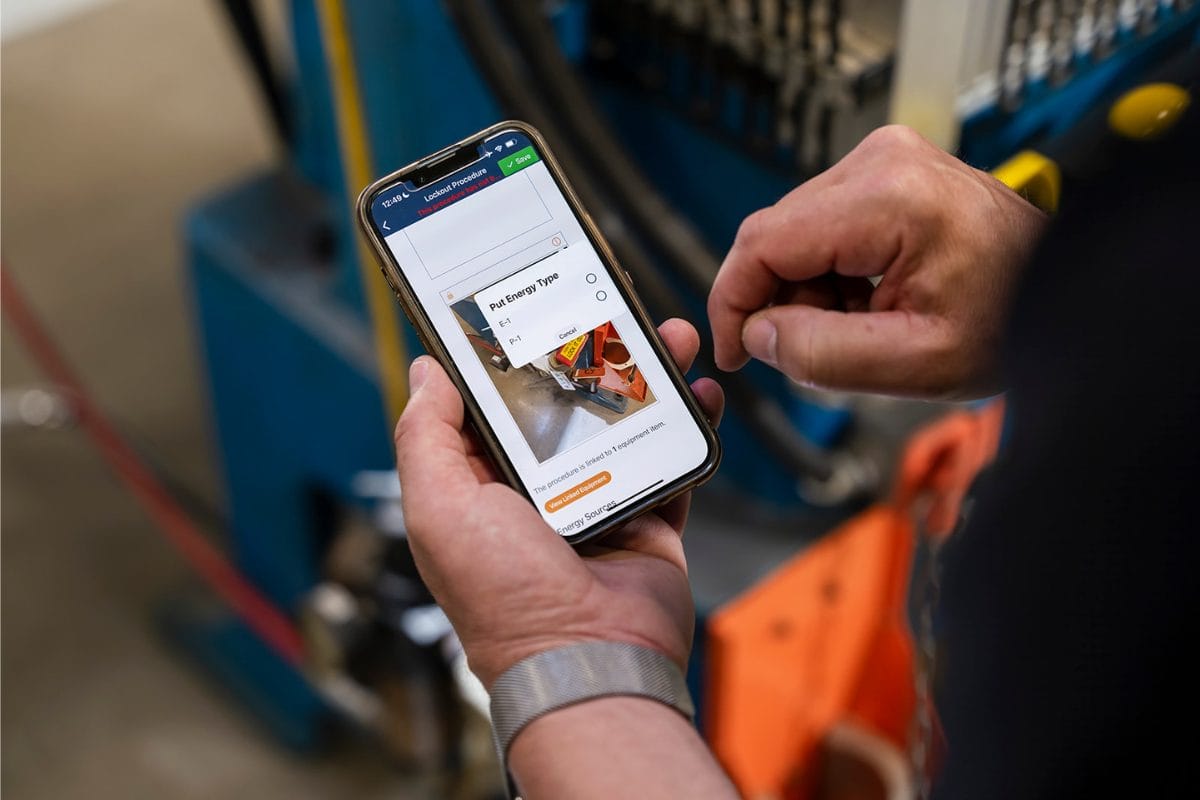

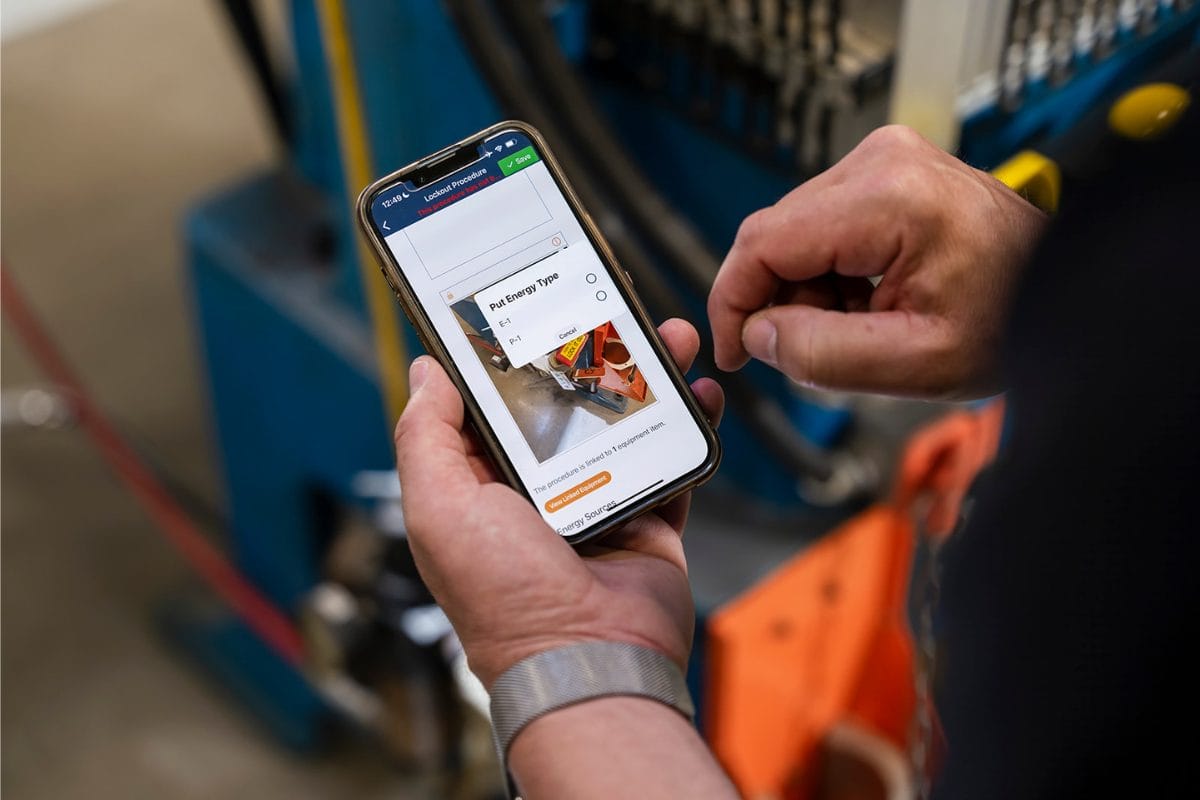

Digitizing lockout tagout procedures may sound complicated, but it doesn’t have to be. With InspectNTrack Smart Safety software, you can easily transfer your procedures into the platform within a couple of minutes. It’s a painless process that requires minimal time and effort to make your job SO much easier.

Let’s get into the steps for creating easy-to-access digital lockout tagout procedures . Here’s how:

Benefits of Digital Lockout Tagout Procedures

Digitizing your lockout tagout procedures is a small investment that comes with many benefits. Let’s take a look at the value that can be gained by putting your procedures in a digital format.

Conclusion

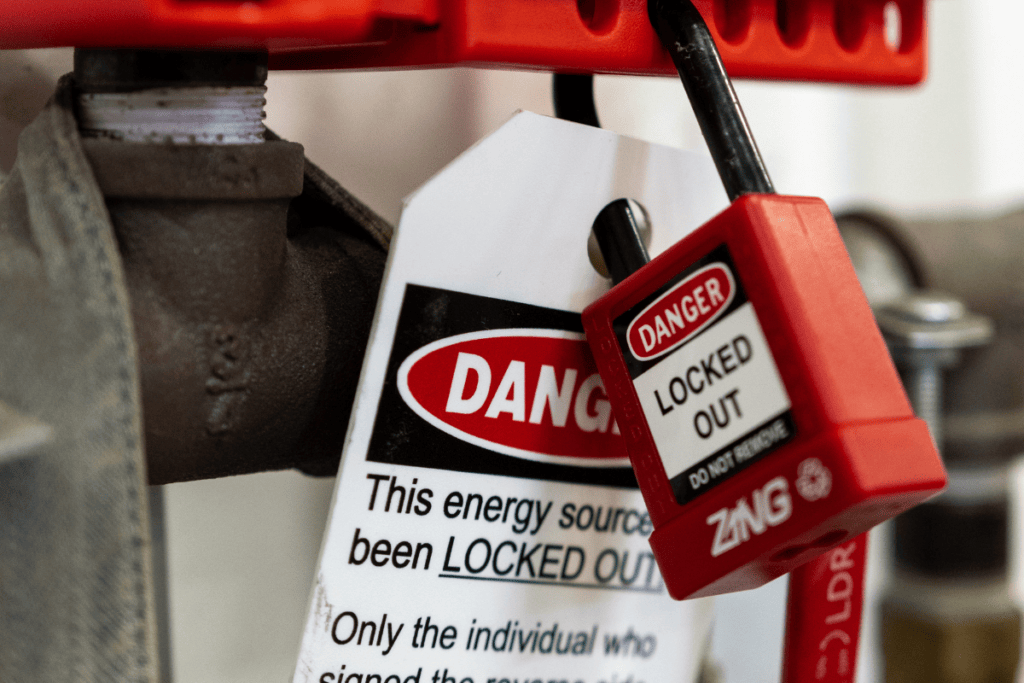

Digitizing lockout tagout procedures is a simple and quick process that can help you improve safety, compliance, and accessibility. Traditionally, LOTO programs have relied on loose papers for documenting their procedures, which has many drawbacks. Thankfully, software solutions like InspectNTrack Smart Safety make it easy to convert your procedures into a digital format. With lockout tagout software, you can create procedures in a couple of minutes and verify that they include all the necessary information. Other benefits of digitizing procedures include increased accessibility, improved compliance, adjustability, and savings.

Benefits like these are why so many companies are making the switch. Want to learn more about how you can leverage technology in your lockout tagout program? Schedule a demo with one of our specialists today.