CNC machines are the workhorses of modern manufacturing. From milling and turning to drilling and grinding, they keep production moving at high speed and with pinpoint accuracy. But behind all that precision lies a serious safety concern: hazardous energy. This is why CNC machine LOTO (Lockout/Tagout) is not just a compliance requirement, it’s a life-saving procedure that every shop must take seriously.

In this article, we’ll break down why CNC machines require special attention when it comes to lockout/tagout, what steps every shop should follow, and how to keep your procedures practical, effective, and OSHA-compliant.

Why CNC Machine LOTO Matters

CNC machines may look harmless once the spindle stops turning, but they can store and release dangerous energy in ways that aren’t always obvious. Electrical circuits, hydraulic clamps, pneumatic systems, and even stored mechanical energy in moving parts can all create hidden hazards.

Without proper CNC machine LOTO procedures, workers performing maintenance or repair risk serious injury, including:

- Electrical shock from live circuits

- Crushing or pinching from moving axes or hydraulic components

- Entanglement in residual spindle movement

- Accidental machine startup during troubleshooting

According to OSHA, lockout/tagout violations are consistently among the top ten workplace safety citations each year. That means CNC shops that don’t prioritize LOTO not only put workers at risk but also open themselves up to costly penalties.

Common Energy Sources in CNC Machines

Before developing an effective CNC machine LOTO program, it’s essential to identify all possible sources of hazardous energy. Typical CNC machines can include:

- Electrical: Power to drives, motors, and control circuits

- Hydraulic: Clamping systems, tool changers, and coolant pumps

- Pneumatic: Air-driven tool changers or spindle brakes

- Mechanical: Stored energy in gears, springs, or moving axes

- Thermal: Heat from spindles, motors, or cutting processes

Each of these energy sources must be isolated, locked, and verified before any work begins.

Step-by-Step CNC Machine LOTO Procedures

A solid CNC machine LOTO process follows the OSHA standard but is tailored to the specific machine type and shop environment. Here’s a streamlined version of what every shop should implement:

-

Preparation

- Review the machine-specific lockout procedure.

- Identify all energy sources that need to be isolated.

-

Shutdown

- Power down the machine using the normal operating controls.

- Stop the spindle, feed axes, and coolant pumps.

-

Isolation

- Disconnect and lockout the main electrical supply.

- Shut and lock valves for hydraulic and pneumatic lines.

- Isolate any auxiliary systems (coolant or lubrication pumps).

-

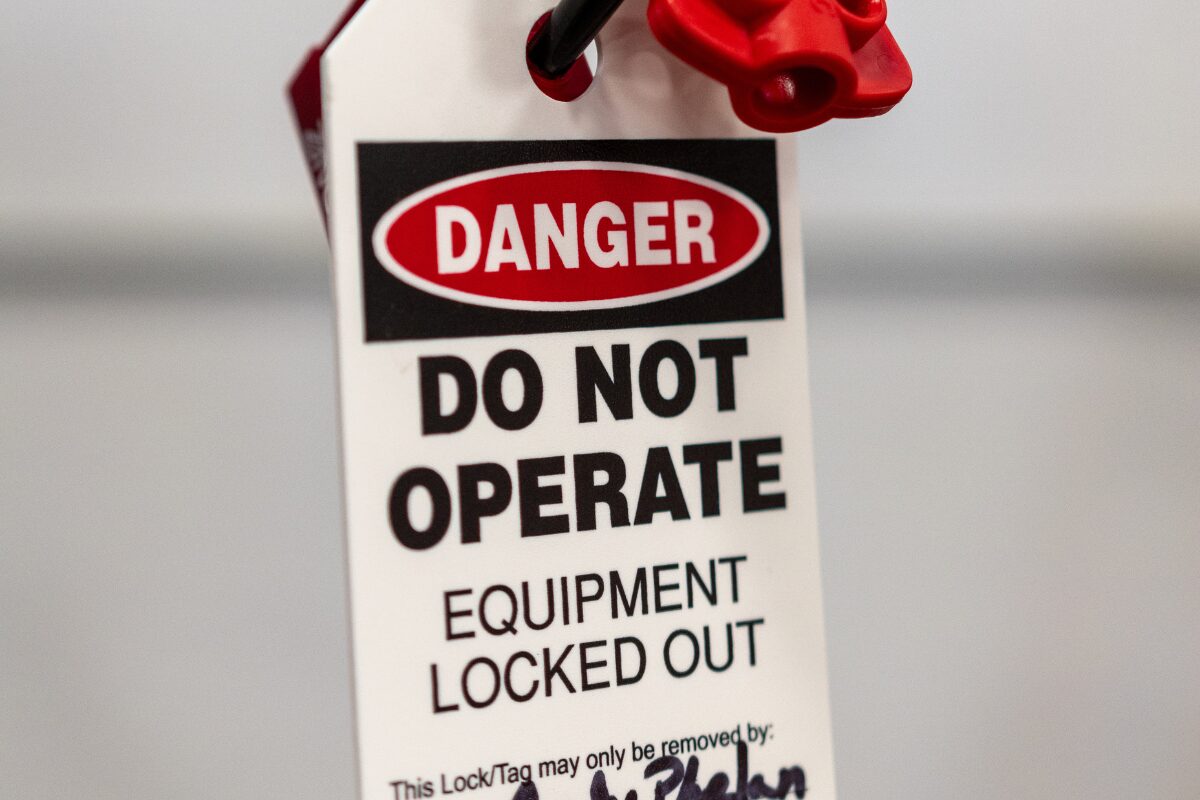

Lock and Tag

- Apply locks to each isolation point.

- Attach clearly marked tags indicating who applied the lock and why.

-

Release Stored Energy

- Bleed hydraulic and pneumatic pressure.

- Verify that all moving parts have come to a complete stop.

-

Verification

- Attempt to start the machine to ensure it cannot power on.

- Double-check gauges, displays, and controls to confirm zero energy.

-

Perform Maintenance

- Only after these steps is it safe to begin repair, cleaning, or adjustment.

-

Restoration

- Once work is complete, remove locks and tags according to procedure.

- Re-energize systems gradually and confirm safe operation before resuming production.

Best Practices for CNC Machine LOTO

While the steps are straightforward, the biggest challenge is ensuring workers follow them consistently. Here are some proven best practices:

- Create machine-specific procedures with diagrams and clear isolation points.

- Train employees annually and test their knowledge with hands-on demonstrations.

- Use standardized lockout devices that are color-coded and compatible with your machines.

- Audit procedures regularly to ensure they remain accurate after equipment modifications.

- Encourage a culture of safety where employees don’t feel pressured to bypass LOTO for the sake of production.

Beyond Compliance: Building a Safer Shop

Following CNC machine LOTO procedures isn’t just about avoiding fines. It’s about protecting skilled operators and maintenance personnel who keep your shop running. When workers know their safety comes first, morale improves, turnover decreases, and productivity often rises.

By investing the time to implement clear, consistent lockout/tagout practices, CNC shops can transform safety from a regulatory headache into a competitive advantage.

CNC machines are complex, powerful, and essential to modern manufacturing. But they also carry risks that can’t be ignored. With proper CNC machine LOTO procedures in place, shops can eliminate hidden hazards. They can comply with OSHA standards and, most importantly, ensure that every worker goes home safely at the end of the day.

Lock it out. Tag it out. And keep your shop both productive and safe.