Not sure who should participate in lockout tagout procedures? This article provides a simple overview of the roles and responsibilities in lockout tagout procedures.

Lockout tagout is an essential safety measure in many industries. However, if done incorrectly, it can become a real danger to those involved. As a result, it is imperative that personnel understand what lockout tagout is, how it functions, and only get involved if they are needed. In this article we will review lockout tagout procedures along with the roles in LOTO, so that you can know your place and maximize safety in your work environment.

What Is a Lockout Tagout Procedure?

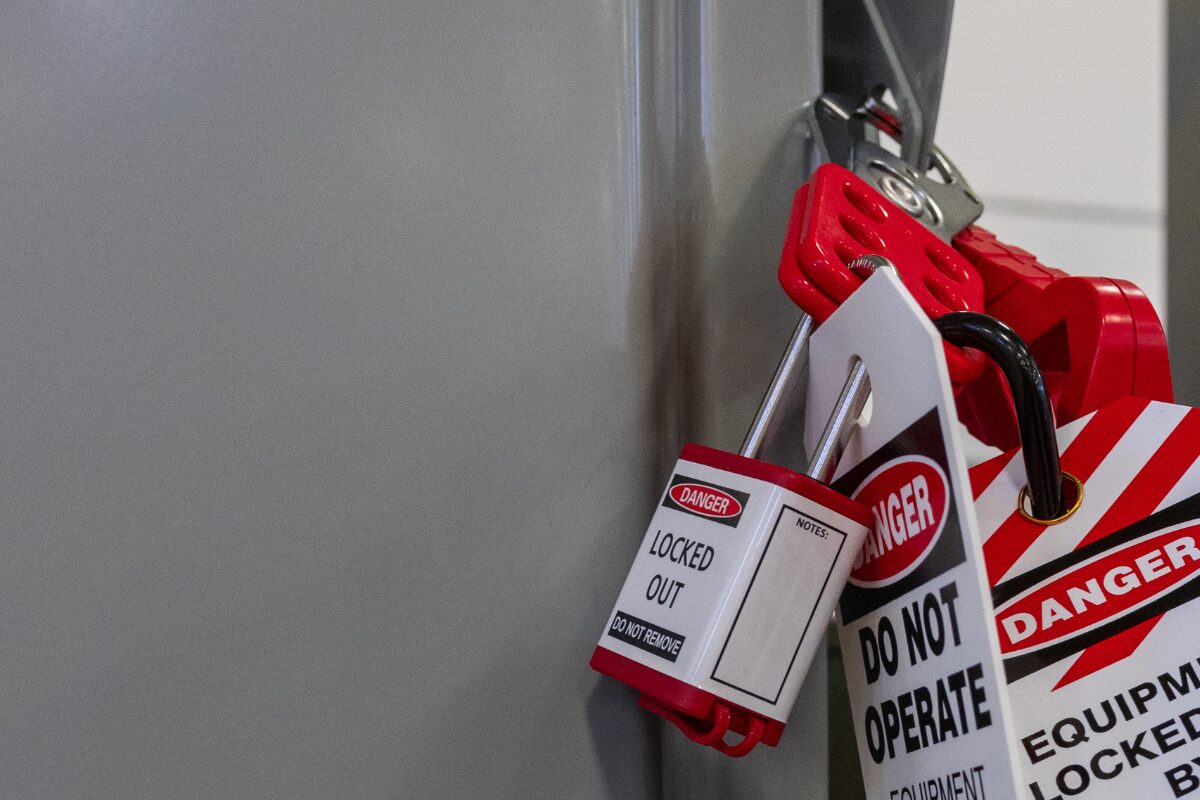

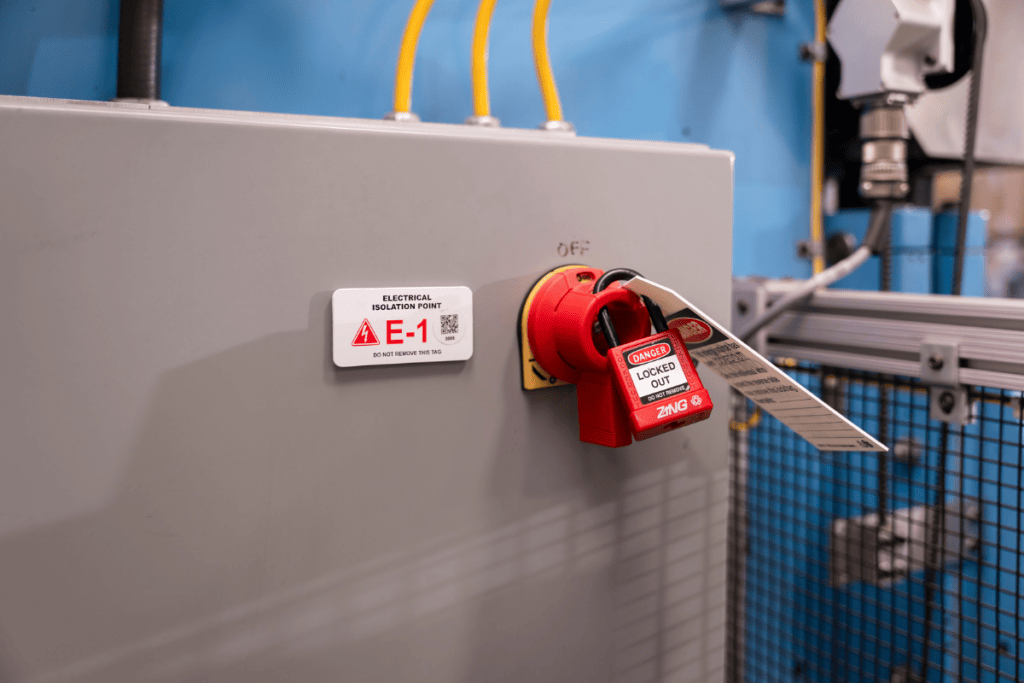

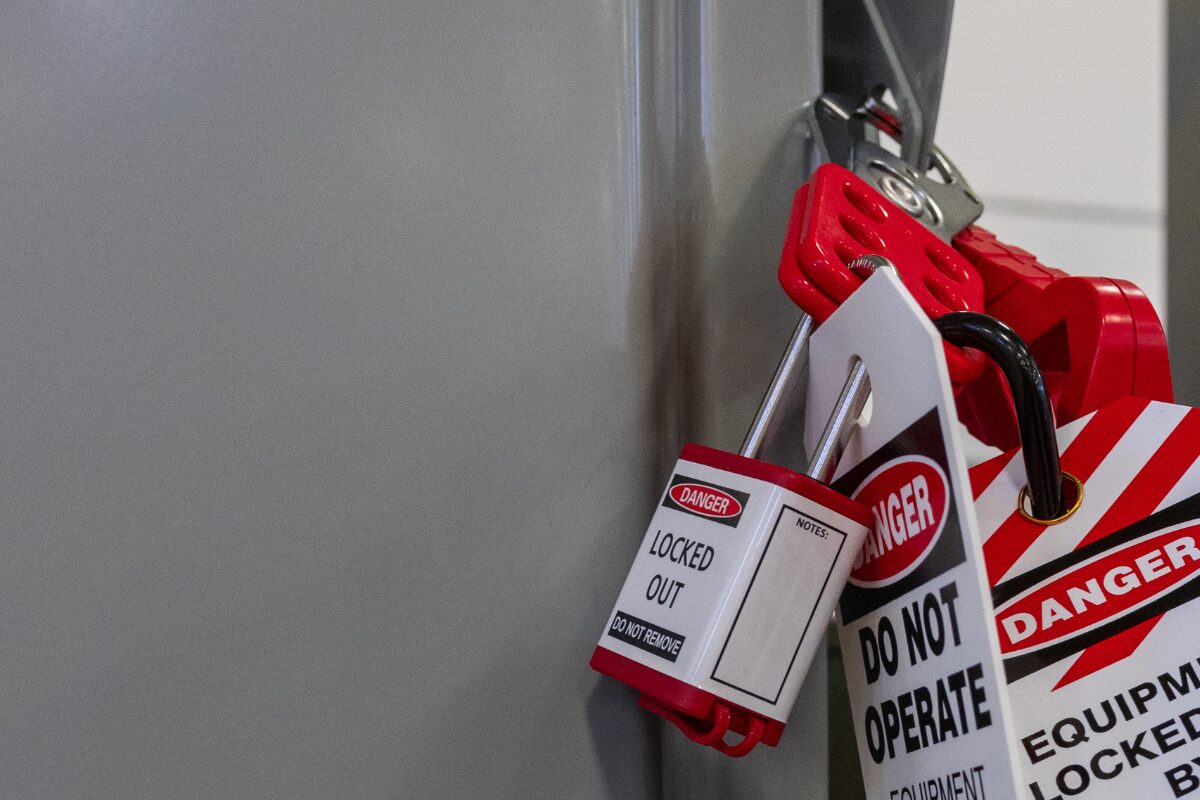

A lockout tagout procedure is a set of instructions that provide an authorized employee with adequate information to safely perform LOTO. These procedures should be machine-specific and typically provide information about how to identify and isolate energy sources, pointers about applying LOTO devices, steps for machine shutdown, and return to service steps. When conducted properly, lockout tagout procedures allow workers to safely conduct work on machinery and equipment by controlling any and all hazardous energy.

Roles in Lockout Tagout

Lockout tagout procedures impact both those who are performing them as well as others in the facility. Because of this, employees who work in an environment that requires lockout tagout can fall into 4 categories: Management, authorized employees, affected employees, and others.

Who Needs to Be Involved?

When it comes to LOTO, authorized employees are the only people who should ever actually perform lockout tagout procedures and apply/remove the locks, tags, or other LOTO devices.

However, safety isn’t a single individual’s responsibility or problem. Many others are involved in creating a safe environment.

Here are ways that individuals might be involved in lockout tagout procedures:

- Safety Managers: Leadership should be involved by making lockout tagout procedure assignments, overseeing that those procedures are done correctly, and verifying that procedures are properly documented.

- Affected Employees: These workers need to communicate with authorized employees to know when their machinery has been returned to service and they can resume their normal work.

- Other Employees: It is important for workers who are near LOTO but not directly impacted by it to understand what lockout tagout is and refrain from touching or interfering with any of the procedures.

It’s also important to note that group lockout tagout procedures generally require the involvement of more people than traditional procedures. Typically there is a bit more involvement from supervisors along with more than one authorized employee working on the equipment.

Conclusion

In the workplace, safety needs to be a goal that everyone is striving for. However, when it comes to LOTO, performing lockout tagout procedures is a job that needs to be overseen by leadership and conducted by authorized employees. Personnel whose work is affected by procedures should stay aware of the situation, but restrain from getting involved. By abiding by these guidelines, those who need to be involved can get the job done safely and efficiently, creating a more secure work environment.