This article provides an explanation for the purpose and importance of lockout tagout periodic inspections along with information to help you complete them successfully!

Why do you go to a well-checkup at the doctor’s office? Or get a maintenance check on your car? We do these tasks, because regular check-ins provide the opportunity to see what is working well, identify problems, and assess how to remedy any current issues. The same is true for periodic inspections of safety programs.

Periodic inspections are a routine check-in used to evaluate lockout tagout (LOTO) programs and ensure that everything is in order. In this article we will do a deep dive into what periodic inspections are, why they are significant, consequences of negligence, and how to perform them effectively. Now, let’s get into it!

What are Periodic Inspections?

Let’s start by getting on the same page about what periodic inspections are.

A periodic inspection is an OSHA-mandated evaluation of a company’s lockout tagout program. Or in simpler terms, it is a government requirement meant to ensure that businesses that use machinery with hazardous energy are properly training their employees and following the process of lockout tagout.

Per OSHA 1910.147, periodic inspections should be performed at least once a year by an authorized employee other than the one(s) performing the lockout tagout procedure. During inspections, this person is deemed the “inspector” and is responsible for determining whether the steps of the energy control procedure are being followed, if the employees involved understand their responsibilities and how effective the procedure steps are in providing the necessary protection.

The main points of periodic inspections include:

- Reviewing lockout tagout procedures for specific equipment.

- Observing workers as they carry out LOTO tasks.

- Ensuring that the procedures are up-to-date and compliant with current standards.

- Providing feedback and any necessary corrective actions, including re-training.

The Purpose of Periodic Inspections

As mentioned earlier, periodic inspections are similar to doctor’s visits or car maintenance in that they are critical for diagnosing problems, assessing overall health, and creating treatment plans for issues. Their overall purpose is to maximize effectiveness and minimize future issues.

Here are some specific purposes for conducting periodic inspections and how they can benefit your lockout tagout program:

- Verify Compliance: Annual inspections are a regulatory requirement for compliance. Therefore performing them each year fulfills that requirement. Additionally, inspections provide the opportunity to see if employees are actually adhering to the established LOTO procedures and performing them correctly and consistently.

- Identify Gaps in Your Operations: Over time, there may be changes to your machinery, processes, or even safety regulations. Inspections are a way to identify these changes and ensure that lockout tagout procedures are adapted accordingly.

- Assess Employee Training/Understanding: Employees may become complacent with procedures they are familiar with or misinterpret procedures if they aren’t properly trained. Periodic inspections highlight areas where additional training or clarification may be required.

- Reduce the Likelihood of Injuries: Ultimately, the goal of periodic inspections is to prevent accidents by ensuring that LOTO procedures are rigorously followed. Even minor mistakes in lockout tagout can have fatal consequences, making inspections critical for workplace safety.

4 Ways Periodic Inspections Contribute to Program Safety

Periodic inspections may feel like an additional box to check, but they are much more than that. These routine inspections play an important role in maintaining a safe work environment.

Let’s look at 4 primary ways that periodic inspections can strengthen your program and improve workplace safety:

Consequences of Neglecting Periodic Inspections

So far we’ve discussed what periodic inspections are, their purpose, and some benefits for completing them, but what happens if you DON’T keep up with periodic inspections? Failing to conduct periodic inspections can have serious consequences, both for safety and compliance. These include:

- Increased Risk of Injury: Without regular inspections, procedural errors or omissions can go unnoticed. These mistakes can lead to accidents, injuries, or even fatalities.

- Non-Compliance with OSHA: OSHA mandates that periodic inspections be conducted at least annually. Failing to comply with this requirement can lead to citations, fines, and legal liability.

- Degraded Program Effectiveness: A LOTO program that is not routinely inspected will degrade over time. Procedures may become outdated or irrelevant as equipment changes, leading to lapses in safety.

- Loss of Employee Confidence: When employees see that safety procedures are not being regularly evaluated or enforced, they may lose confidence in the program and stop taking it seriously, leading to careless behavior.

As you can see, it is in the best interest of your program to perform periodic inspections. They can come with some serious benefits for safety and also serious consequences for negligence. So what can you do to make sure that your program approaches them in the best way?

Tips for Simplifying Periodic Inspections

While inspections are essential, they can sometimes feel daunting to complete. However, with the right approach, periodic inspections can become simple and efficient.

Pointers for Making Periodic Inspections Easy

Manage Your Program Better With Lockout Tagout Software

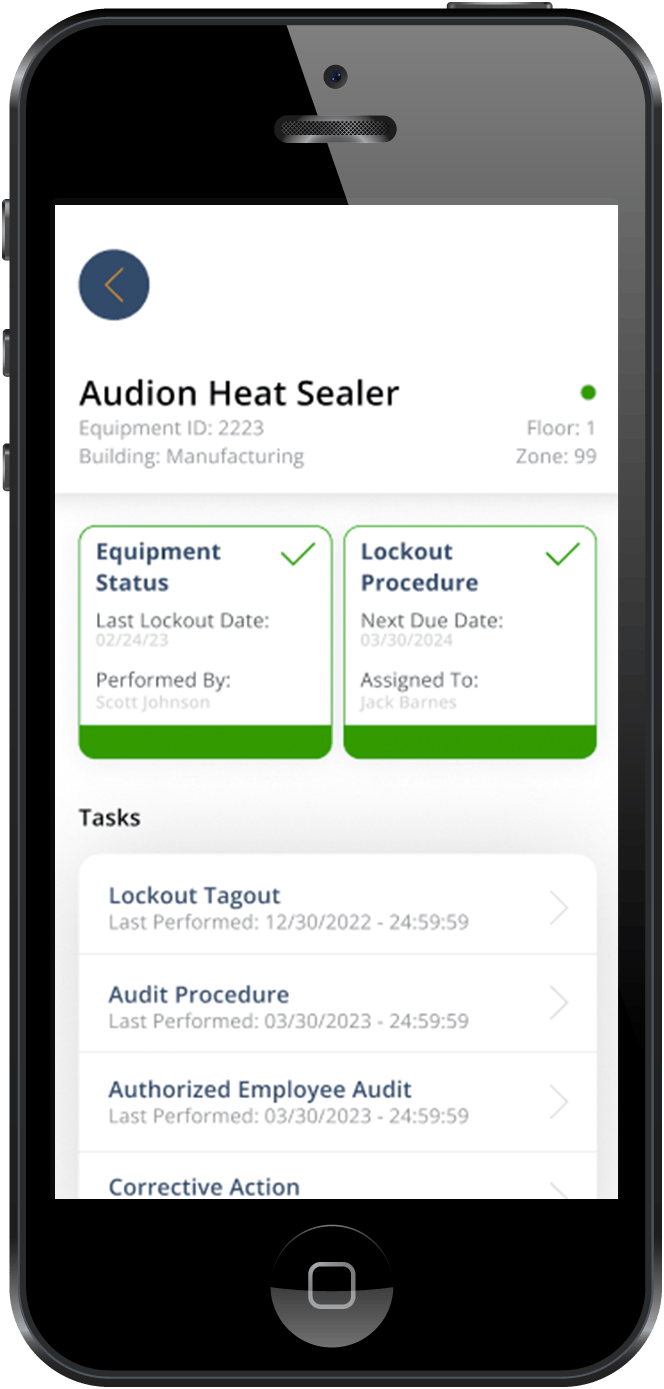

As time goes on, more and more companies are making the switch and integrating software capabilities into their lockout tagout programs. With benefits such as paperless documentation and real-time updates, integrating digital lockout tagout with software is a no-brainer for a lot of organizations. However, it makes sense to be hesitant or want to learn what you can before diving in.

At InspectNTrack Smart Safety, we don’t want you to just choose our software, but we want you to love your choice. To help you decide whether or not our program works for your situation, we offer free demos.

With a free demo, you can set up a time to meet with one of our professionals and talk about your organizational needs. This way, you can gather information and make an informed decision about what’s right for your company’s future.

Click here to learn more about how Smart Safety Pro can enhance your lockout tagout program.

Conclusion

Periodic inspections are vital for a well-functioning Lockout Tagout program. They act as a form of check-up that can assess your program’s overall health, identify gaps, and reinforce safe practices. Not only that, but they help to verify compliance, prevent accidents/injuries, and encourage a culture of safety. If that isn’t reason enough to perform them, neglecting to perform periodic inspections can come with serious consequences including fines and violations. Therefore, it is in your organization’s best interest to make inspections a high priority.

Some things that can simplify inspections include planning ahead, involving employees, and utilizing software. Lockout tagout software can be a real game changer for LOTO program management. By taking periodic inspections seriously and utilizing software, you can best set your organization up for LOTO success!