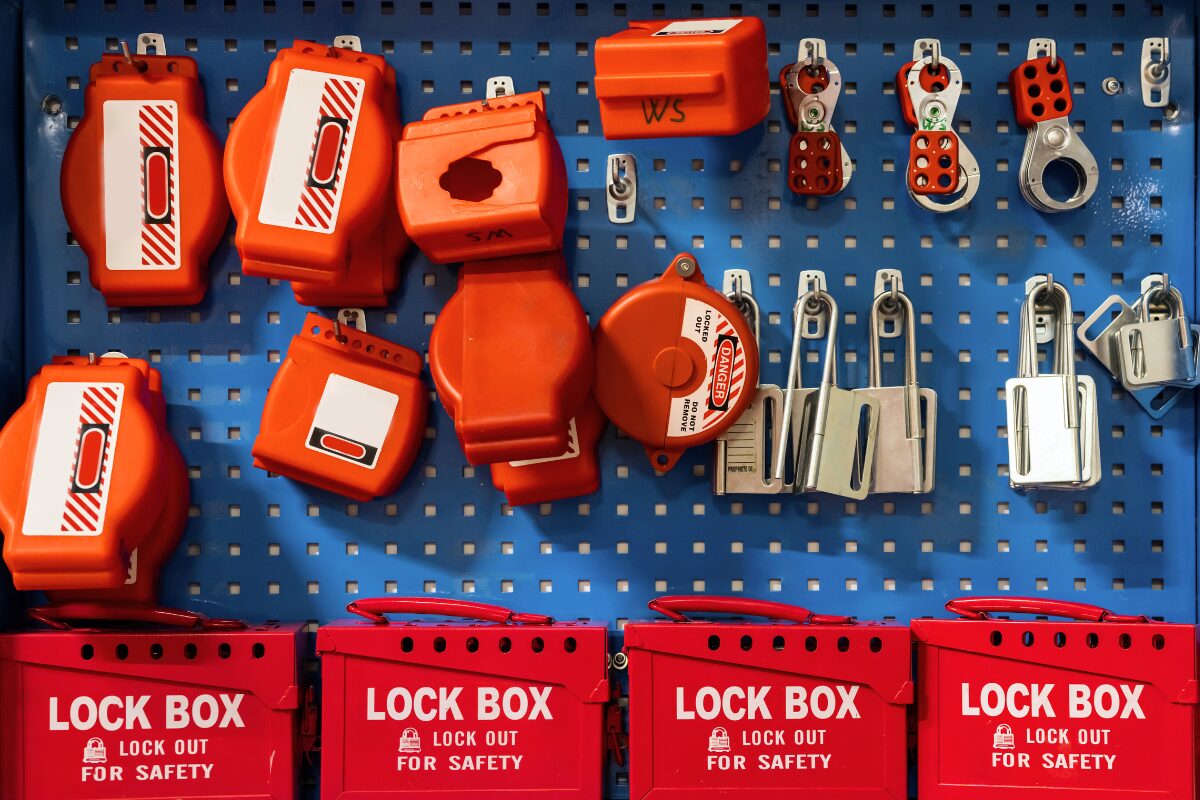

Mobile Periodic Inspections

Periodic Inspections are often considered the hardest part of OSHA 1910.147 compliance. They normally require manual tracking, planning, paperwork, and data entry. The process is cumbersome and hard to succeed at. Smart Safety Lockout Tagout takes over all the manual processes so that you can spend your time focused on the actual intent of the standard: training employees and keeping your facility safe.

“A lot of companies don’t have systems in place to be able to manage the periodic inspection process, and it can be very challenging. With InspectNTrack Smart Safety, you can go out there and just bring procedures up on the fly and do a mobile periodic inspection. Make that part of your daily life. Then you can go on the web and you can see, we still have these 10 that we didn’t hit and then we do a planned event on those.”

Periodic Inspections

The InspectNTrack Smart Safety lockout tagout app maintains records of all periodic inspections at the individual equipment level.

The mobile periodic inspections module displays equipment with periodic inspections due at 30, 60, or 90 day intervals.

Anywhere, Anytime

Mobile periodic inspections can be performed on demand, promoting the ability to make them part of the daily job rather than doing them all at once.

Mobile Periodic Inspections Benefits

Mobile periodic inspections are superior to traditional, paper based options

Get In Touch

Want to Learn More About Mobile Lockout Tagout?

Drop us a line and we’ll reach out with more information about our LOTO software.

Featured FAQs

Frequently Asked Questions

Check out the answers to frequently asked questions about the Smart Safety Lockout Tagout software program.